A1000 THICKNESSING MACHINE

A thicknessing machine designed to peel a layer of wood to achieve a specific thickness. The A1000 series thicknessing machines feature a sturdy cast iron table with a planed surface. The table is lifted on four trapezoidal screws, which are guided by four ∅60 posts. The table is embedded in a rigid body, which makes it possible to obtain the highest machining quality. A hallmark of the machine is its state-of-the-art design. As a standard, the machine features automatic workpiece thickness adjustment, seamless feed adjustment, two smooth rollers behind the blade shaft and a spiral feed roller. An additional advantage of the machine is the high-performance blade shaft equipped with four planing blades with three adjustment screws on each one.

Technical specification

|

Parameters |

Units |

Dimension |

|---|---|---|

|

Maximum |

mm |

1000 |

|

Minimum planed material thickness |

mm |

3 |

|

Maximum planed material thickness |

mm |

300 |

|

Maximum planed layer thickness |

mm |

8 |

|

Minimum workpiece length |

mm |

400 |

|

Stepless feed rate |

m/s |

4-20 |

|

Diameter of chip extraction nozzle |

mm |

160 |

|

Air velocity in the chip extraction system |

m/s |

24 |

|

Air demand |

m3/h |

1750 |

|

Main motor power |

kW |

15 |

|

Feed motor power |

kW |

3 |

|

Lifting motor power |

kW |

0,37 |

|

Machine tool weight |

Kg |

1600 |

|

Overall dimensions: |

mm mm mm |

1200 1640 1300 |

Standard equipment

TABLE LIFTED ON FOUR COLUMNS

The table is lifted on four trapezoidal screws guided by four linear guide rails. This makes it possible to achieve very high machine rigidity and the highest precision for table positioning.

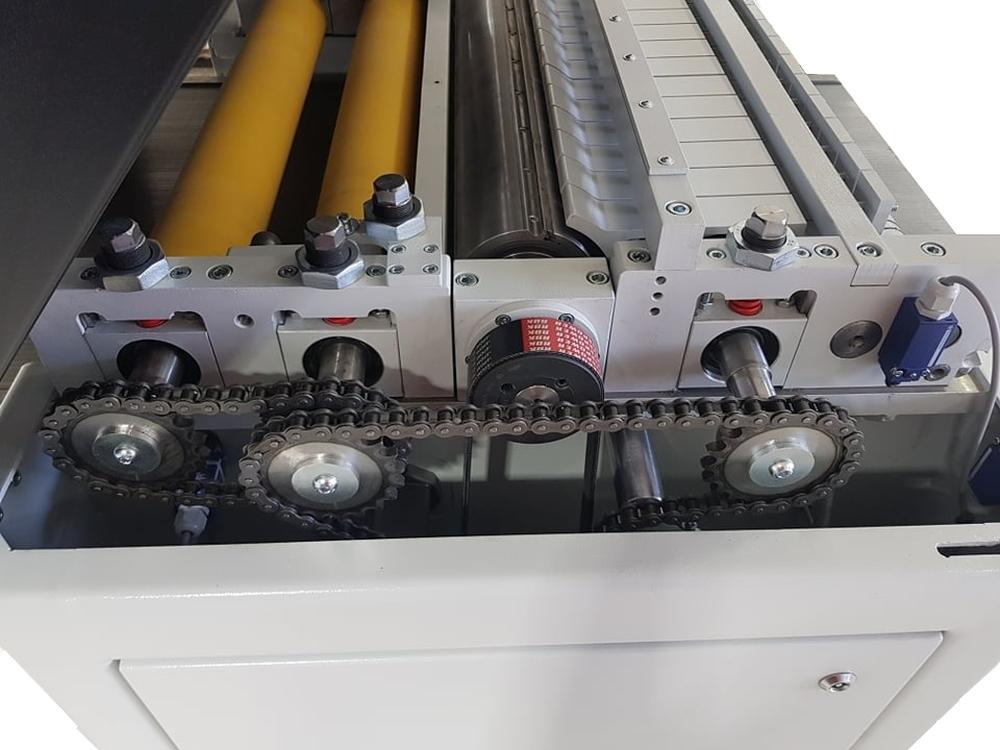

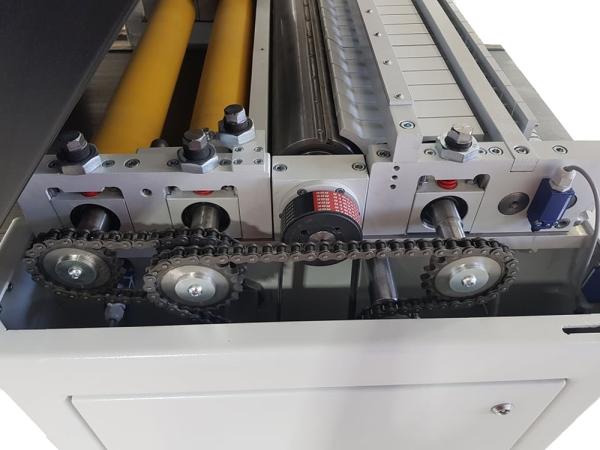

TWO SMOOTH ROLLERS BEHIND THE BLADE SHAFT (STANDARD)

As a standard, the MADORA thicknessing machines are equipped with two smooth rollers at their outlet to keep the material stable during machining, resulting in a high surface quality of the machined material.

SPIRAL FEED ROLLER (STANDARD)

A spiral feed roller ensures a very consistent feed, which influences the quality of the machined surface.

STEPLESS FEED ADJUSTMENT (STANDARD)

Each MADORA thicknessing machine enables stepless feed adjustment, improving the operator's experience when handling the machine.

SPRING-LOADED SPLIT BAR (STANDARD)

Located in front of the blade shaft, the spring-loaded split bar is particularly useful when processing thin workpieces and uneven input material. (Sturdy cast iron clamps)

AUTOMATIC ADJUSTMENT OF MACHINING THICKNESS (STANDARD)

By far the greatest distinguishing feature of the MADORA thicknessing machine is the automatic table positioning system, which greatly facilitates the operation of the machine.

Optional equipment

TABLE ROLLERS (OPTIONAL)

Fitting the table with rollers facilitates the processing of wet and resinous wood.

TABLE EXTENSION ROLLERS (OPTIONAL)

Additional rollers on entry and exit make it easier to work when machining long workpieces.

SEGMENTED FEED ROLLER (OPTIONAL)

The segmented roller facilitates work when machining workpieces of uneven thickness. The roller's flexible segments seamlessly adapt to the thickness of the input workpiece.

PNEUMATIC CLAMPING FORCE ADJUSTMENT (OPTIONAL)

Pneumatic adjustment allows the operator to quickly change the clamping force on the individual segments of the feed unit.