GP 600 ZZ

Product description

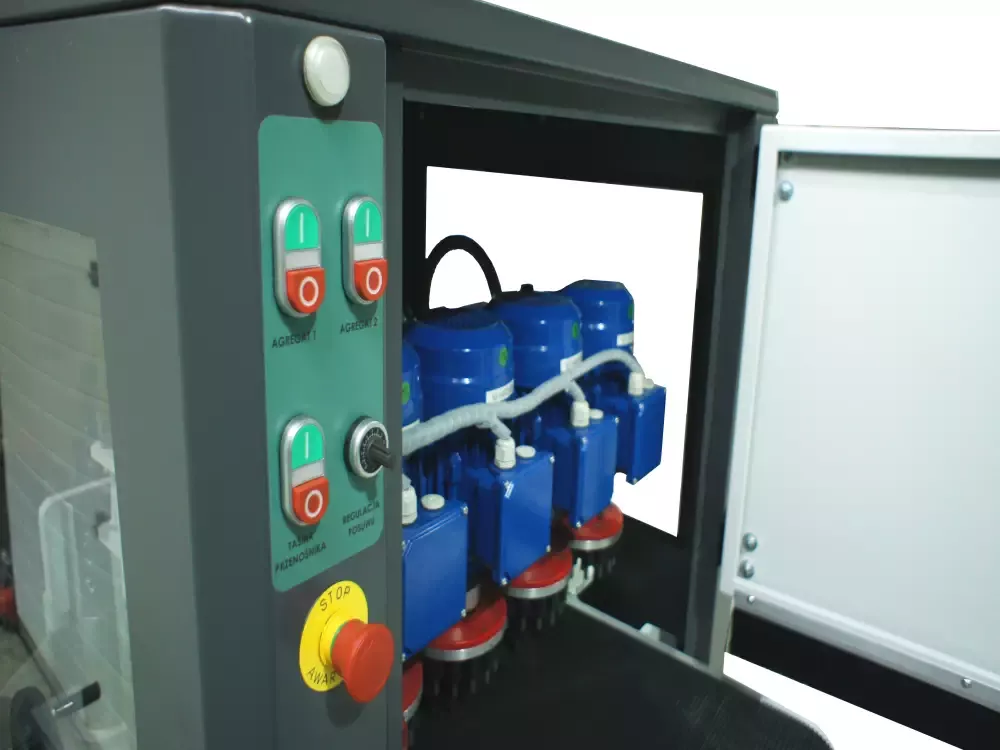

The smallest of the MADORA range, the GP 600 ZZ is a multipurpose deburring machine for cleaning sheet metal after various cutting processes. Featuring two "Z" type machining units, it is characterised by excellent versatility and machining capacity. The deburring machine can perform two operations at the same time: not only does it allow you to remove scale after plasma cutting, but it also makes it possible to deburr or round off the edges of workpieces after laser cutting, all in a single pass. The range of machining thicknesses and widths up to 600 mm make it possible to process small and medium-sized workpieces. With the right tools, the machine is also suitable for heavy edge rounding and oxide removal. The GP 600 ZZ features easy manual controls: the units are positioned manually, which allows you to retain full and continuous control of the machining parameters such as workpiece height, feed rate and tool rotation speed. Each unit can be controlled independently, allowing the operator to decide which machining processes to perform in a single pass.

Technologies:

The GP 600 ZZ is equipped with two "Z" type oscillating and rotating units. Each unit is mounted on four manually adjustable columns, enabling a machining range of 0.5 to 50 mm. The "Z" type units can also be equipped with an inverter so that the operator can seamlessly adjust the tool rotation speed to achieve the desired machining effect.

Each unit can be controlled independently, allowing the operator to decide which machining processes to apply to the workpiece.

Technical specification

|

NAME |

UNIT |

GP600-ZZ |

|

|

MACHINE FUNCTIONS |

|||

|

Descaling (deslagging) |

YES |

||

|

Deburring |

YES |

||

|

Edge rounding |

YES |

||

|

Oxide removal |

YES |

||

|

OPERATING PARAMETERS |

|||

|

Feed rate |

m/min |

0,5-2 |

|

|

Machining thickness range |

mm |

0,5-50 |

|

|

Conveyor belt width |

mm |

600 |

|

|

Table length |

mm |

1300 |

|

|

Machining unit discs |

szt. |

4 |

|

|

GP600-ZZ DIMENSIONS |

|||

|

Width |

mm |

1100 |

|

|

Height |

mm |

1700 |

|

|

Length |

mm |

1500 |

|

|

CONTROLS |

|||

|

TFT operator panel control |

TAK |

||

|

ADDITIONAL EQUIPMENT |

|||

|

300 mm wide magnetic table |

pc. /machining unit |

1 |

|

|

Descaling discs |

pc. /machining unit |

4 |

|

|

Deburring and edge rounding discs |

pc. /machining unit |

4 |

|

|

Flap discs for heavy edge rounding |

pc. /machining unit |

4 |

|

|

Oxide removal discs |

pc. /machining unit |

4 |

|

|

Magnetic plate in the table |

pc. /machining unit |

1 |

|

Abrasive belt unit: featured on all machines with a "P" designation, e.g. the GL1000PZ

Descaling disc (deslagging)

This disk is used for the removal of heavy scale produced by plasma or oxyfuel cutting.

Deburring and edge rounding disc

Disc for light deburring after laser cutting. This disc is also used for edge rounding

Heavy edge rounding disc

Disc for removing light burrs and for performing heavy edge rounding.

Oxide removal disc

Disc for the removal of oxides from the lateral surface of workpieces after laser cutting

Polishing disc

Disc for polishing the surface of stainless steel.