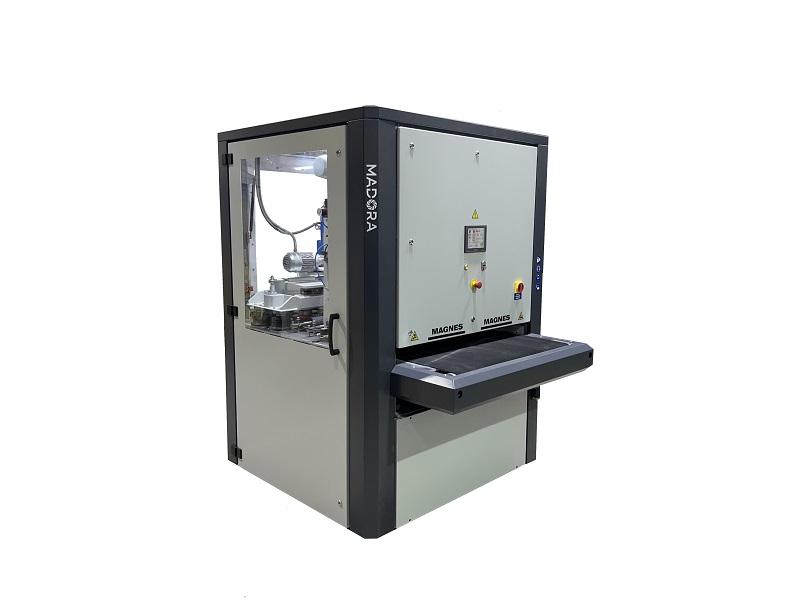

GL 1000 PZZ

Product description

The GL 1000 PZZ series deburring machine is equipped with an abrasive belt unit and two "Z" type oscillating and rotating units. The purpose of the abrasive belt is to collect excess material during the deburring or grinding process. It is the perfect solution whenever the so-called "flashes" and material burns occur, for example after laser cutting. The abrasive belt unit allows you to use various types of sandpaper for specific applications, purposes and results. The "Z" type unit, which is also used in the GL1000 PZZ, makes it possible to finish the workpiece according to the customer's requirements in the final machining stage, for example by deburring or heavy edge rounding, depending on the tools used.

Technologies:

The GL 1000 PZZ is equipped with three units:

an abrasive belt unit and two "Z" type oscillating and rotating units. The machining units have a machining range of 0.5 to 50 mm. The "Z" type units can also be equipped with an inverter so that the operator can seamlessly adjust the tool rotation speed to achieve the desired machining effect.

Each unit can be controlled independently, allowing the operator to decide which machining processes to apply to the workpiece.

Technical specification

|

NAME |

UNIT |

GL1000-ZPZ |

|

|

MACHINE FUNCTIONS |

|||

|

Descaling (deslagging) |

YES |

||

|

Surface grinding |

YES |

||

|

Deburring |

YES |

||

|

Edge rounding |

YES |

||

|

Oxide removal |

YES |

||

|

OPERATING PARAMETERS |

|||

|

Feed rate |

m/min |

0,5-4 |

|

|

Machining thickness range |

mm |

0,5-50 |

|

|

Conveyor belt width |

mm |

1000 |

|

|

Table length |

mm |

2560 |

|

|

GL1000-ZPZ DIMENSIONS |

|||

|

Width |

mm |

1600 |

|

|

Height |

mm |

2250 |

|

|

Length |

mm |

2800 |

|

|

CONTROLS |

|||

|

TFT operator panel control |

YES |

||

|

ADDITIONAL EQUIPMENT |

|||

|

300 mm wide magnetic table |

pc. /machining unit |

1 |

|

|

Descaling (deslagging) discs |

pc. /machining unit |

9 |

|

|

Deburring and edge rounding discs |

pc. /machining unit |

9 |

|

|

Flap discs for heavy edge rounding |

pc. /machining unit |

9 |

|

|

Oxide removal discs |

pc. /machining unit |

9 |

|

|

Magnetic plate in the table |

pc. /machining unit |

2 |

|

The abrasive belt unit is used for heavy burr removal, surface grinding and giving the workpiece surface the right structure. The final machining effect depends on the abrasive paper or cloth used. The abrasive belt unit is ideal for removing the so-called "flashes" after laser cutting, as well as for directional grinding, polishing, etc. During operation, the unit moves in a rotating and oscillating motion over a width of 1,000 mm.

Abrasive belt unit: featured on all machines with a "P" designation, e.g. the GL1000PZ

Abrasive belt

The belt is used for grinding, deburring and deflashing

Deburring and edge rounding disc

Disc for light deburring after laser cutting. This disc is also used for edge rounding

Heavy edge rounding disc

Disc for removing light burrs and for performing heavy edge rounding.

Oxide removal disc

Disc for the removal of oxides from the lateral surface of workpieces after laser cutting